Big Bend Community College students explore battery fabrication at Washington Clean Energy Testbeds

August 21, 2025

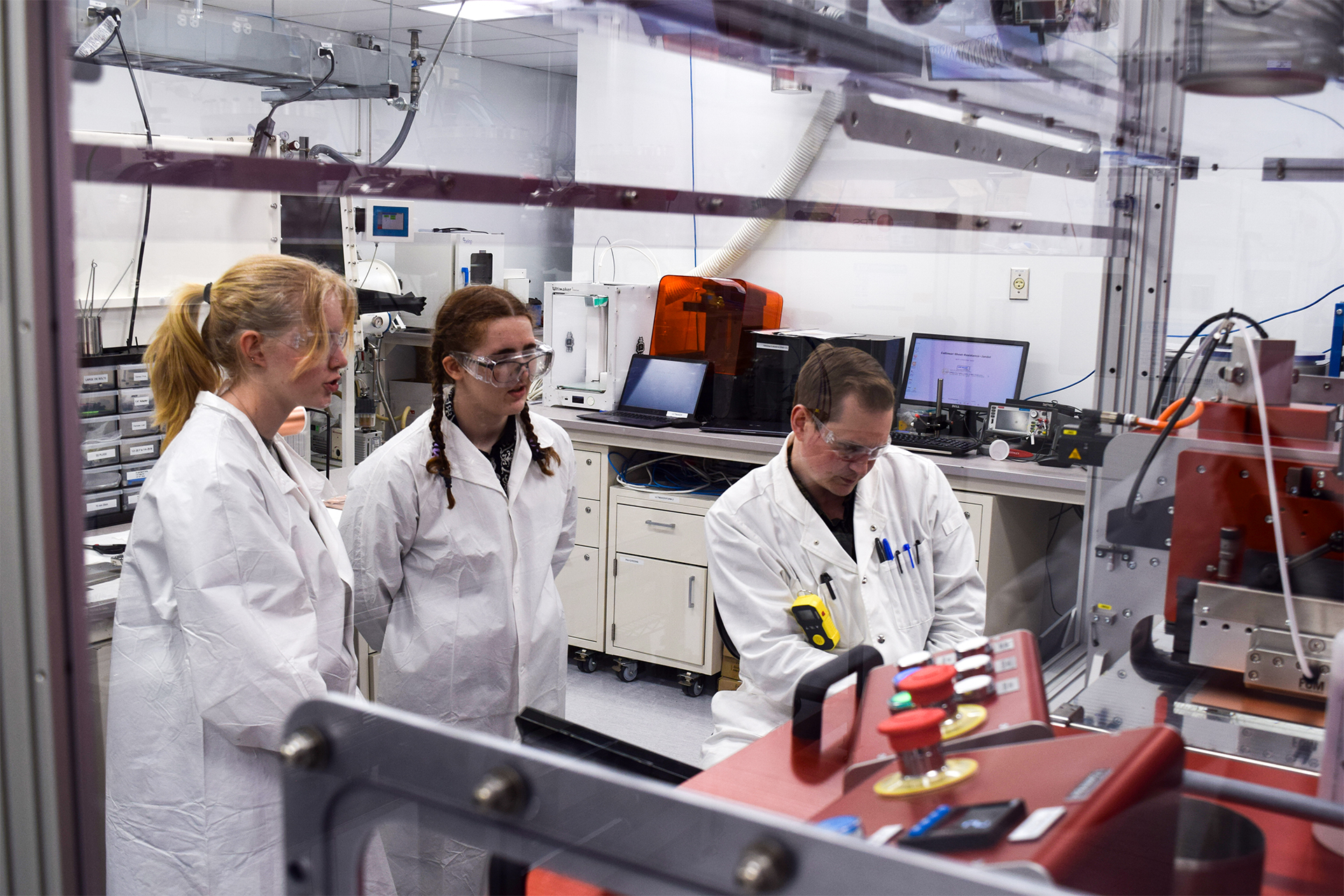

On May 1, 2025, six students from Big Bend Community College in Moses Lake, WA, participated in a battery fabrication workshop at the Washington Clean Energy Testbeds, an open-access lab operated by the University of Washington (UW) Clean Energy Institute (CEI).

The workshop attracted participants from a range of educational and professional backgrounds: Benji Vargas and Koehn Lyons are transferring to the UW this fall to pursue degrees in computer science & engineering and biochemistry, respectively. Jesse Grubbs is a lab manager at an outpatient clinic who’s transferring to Washington State University (WSU) to become a chemical engineer. Mark Mejia-Martinez works full-time in manufacturing with an emphasis on automation and robotics, making manhole covers at D&L Foundry. While Amber Emerson currently envisions a career in civil engineering or architecture, she wants to understand energy storage technologies to help decarbonize the built environment. And Cat Montgomery is an aspiring mechanical or electrical engineer whose fascination with clean energy inspired her to learn more about how batteries are made.

Testbeds technical director J. Devin MacKenzie, the Washington Research Foundation Professor of Clean Energy and an associate professor of materials science & engineering and mechanical engineering at the UW, kicked off the workshop with an overview of battery technology, additive manufacturing techniques like slot-die coating, and how Testbeds users wield the facility’s tools for both academic research and private innovation.

“In [general chemistry], we learned about the principles of voltaic cells, but not the dynamics of modern batteries,” said Grubbs. “But in this workshop, we learned that there’s still space to improve in manufacturing and a lot of challenges in developing new battery technologies.”

“Along with the benefits of additive manufacturing, I learned a lot about battery testing procedures and their safety requirements,” said Vargas. “Understanding the different measurements we use when talking about batteries is also very helpful, even for an everyday consumer.”

MacKenzie is the principal investigator on a Washington State Clean Energy Fund grant to research artificial intelligence-assisted battery manufacturing, which also supports workforce development in Washington’s battery sector. By developing next-generation fabrication techniques and training the next generation of battery engineers, MacKenzie and collaborators aim to onshore this critical sector for the future of our electrified world and the clean energy transition.

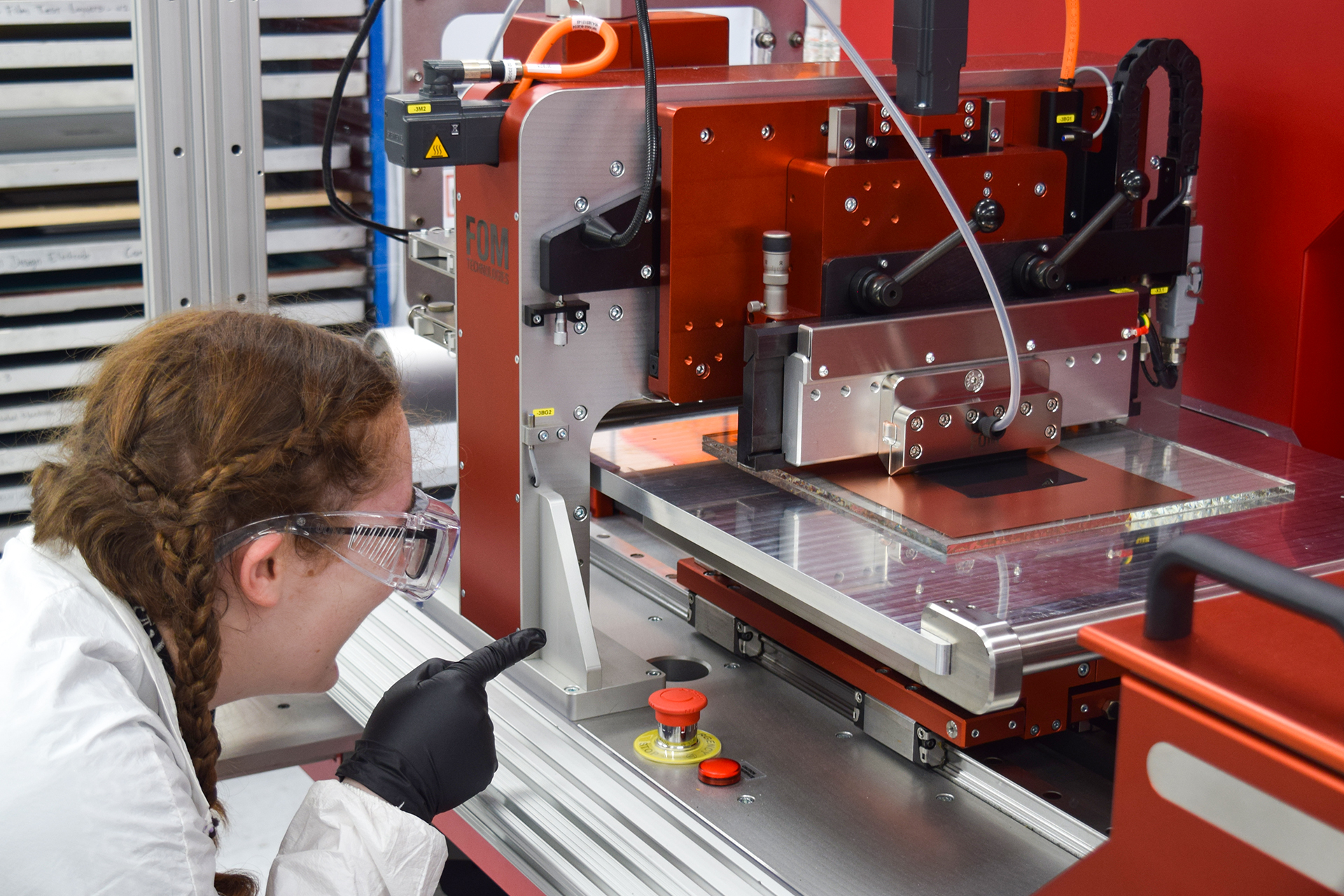

The grant formalizes a partnership between the Testbeds and FOM Technologies, Inc., the U.S. subsidiary of FOM Technologies A/S, a Danish company that makes additive manufacturing equipment such as roll-to-roll coaters. The Testbeds has several FOM instruments across scales and the company opened its U.S. offices out of the facility, where they employ UW graduates.

As a member of Big Bend’s Mechatronics Club, Montgomery was excited to learn about the Testbeds-FOM partnership. “The goal of our club is to solve problems in machining and manufacturing — we have a 3-D printer and we’re building our own CNC [computer numerical control] machine — so I’m curious about how to design experimental equipment,” she said.

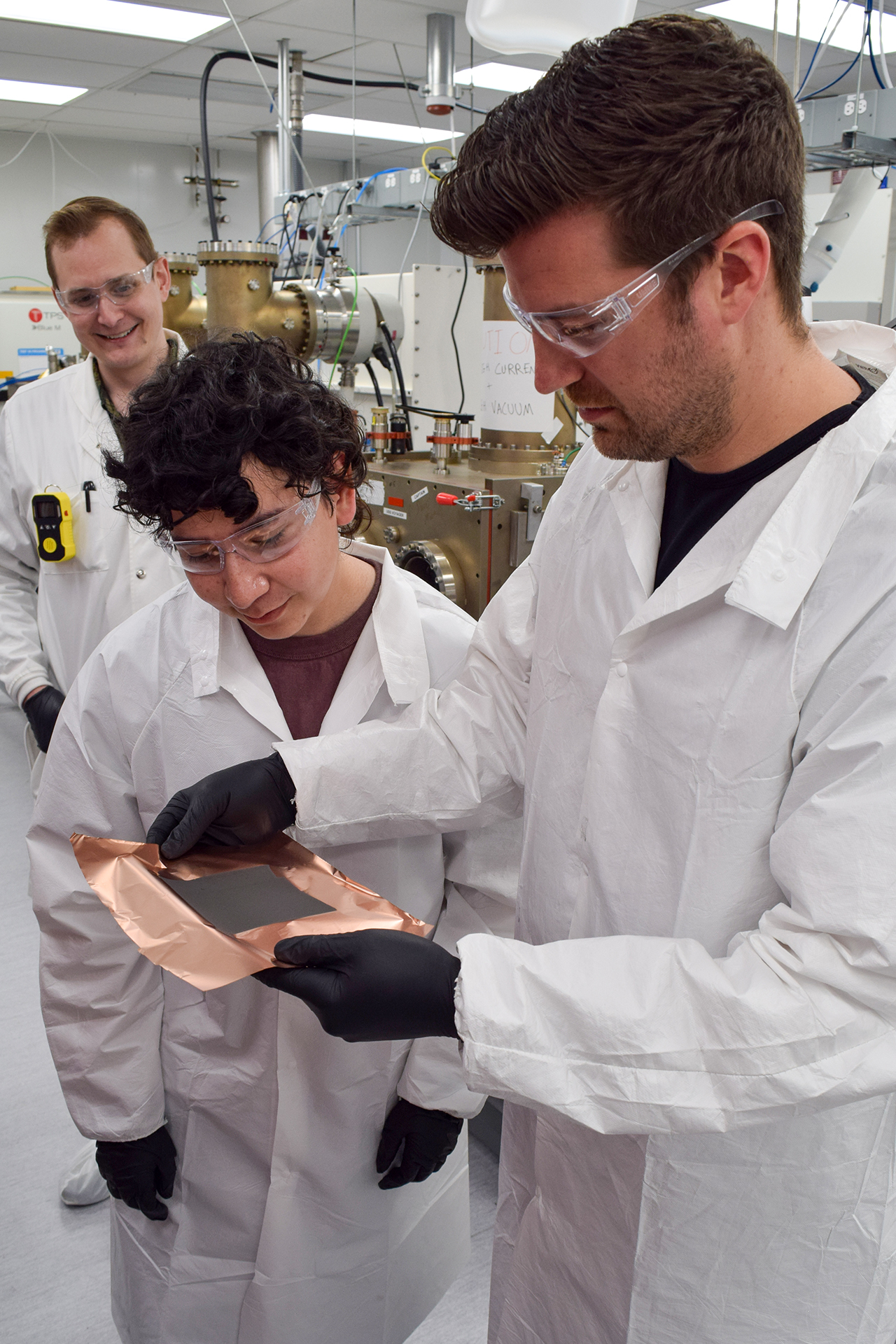

The students worked with Testbeds staff scientists Dr. Tucker Murrey, Sarah Little, and Dr. Phil Cox to learn three key techniques: slot-die coating, coin cell assembly, and battery testing, respectively.

“The workshop also helped show that it’s more realistic to get involved in research than I initially thought,” Grubbs added. “It seemed a little out of reach for an undergrad, but meeting everyone and seeing how things worked helped me realize how accessible resources for research can be, and that it’s not something out of my league.”

Following the workshop, the students visited the Woodinville, WA R&D facility of Group14 Technologies, a global leader in silicon anode materials. Most commercial Li-ion batteries rely on graphite as the negative electrode, which is predominantly produced and refined in China. In recent years, Group14 as well as Sila Nanotechnologies won $100 million federal grants and raised further nine-figure private investments to build silicon anode manufacturing plants in Moses Lake.

“I know there are supply chain problems with some battery materials, and questions about how companies can be sustainable, because prices are going up and the resources aren’t infinite,” Mejia-Martinez said. “With Moses Lake getting new battery facilities, it was important for me to learn about the manufacturing process if I want to work at one of these companies.”

To expand its capabilities for battery innovation at commercially relevant scales, the Testbeds will open a new lab this fall where researchers and companies can prototype batches of pouch cell batteries. This will allow for more rapid validation of new battery materials and cell architectures in a versatile battery format for electric transportation and beyond.

This workshop was supported by the UW College of Engineering and the Clean Energy Institute. Email wcet@uw.edu to learn more about future battery workshops and the new pouch cell battery fabrication lab.